What Are You Looking For?

The ESS battery pack consists of many individual prismatic battery cells, which are encapsulated in a structure that provides structural support, thermal management, and electrical isolation. Designing and efficiently operating ESS battery pack asasembly line is crucial for ensuring the safety, performance, and reliability of the entire energy storage system

Brand :

ACEYItem No. :

ACEY-PAL-ESSCustomization :

OEM&ODM AvailableOrder(MOQ) :

1 SetCompliance :

CE CertifiedPayment :

T/T, L/C, PayPal, West Union, Alibaba Trade Assurance, EtcWarranty :

One Year Warranty With Lifetime SupportProduct Origin :

ChinaPackage :

Internal: Anti-Collision Protectio, External: Plywood CaseShipment :

By Air, Sea, Express, etc.Lithium Ion Battery Pack Module Assembly Line For ESS Energy Storage System

Description

Energy Storage System (ESS) battery packs are a key technology for power storage, widely used in residential, commercial, and industrial scenarios. They can store excess electrical energy and release it when needed, thereby improving energy utilization efficiency and the stability of the power grid.

The assembly line for ESS battery packs includes the following key steps:

*Prismatic Battery Pack Full-Automatic Assembly Line

| Prismatic Battery Pack Semi-Automatic Assembly Line | |

| Product Name | Description |

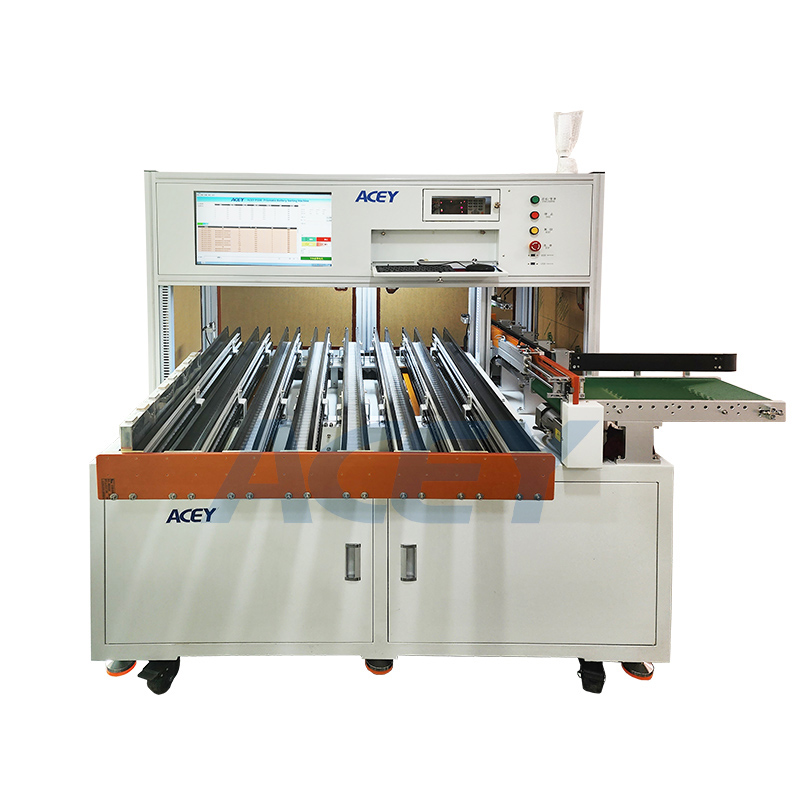

| Battery Cell Grading Machine | 5V 30A/60A/100A/200A/300A Prismatic Battery Tester |

| Battery Sorting Machine | 8 Channels Battery Sorting machine |

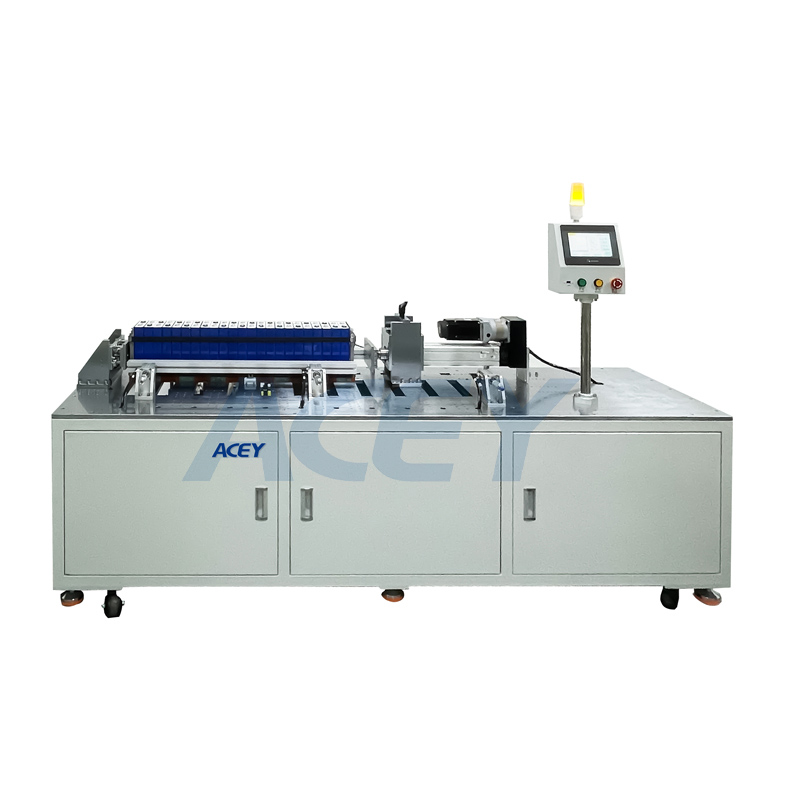

| Battery Stacking Pressing Machine | 50 groups/hour (10PCS battery cells) |

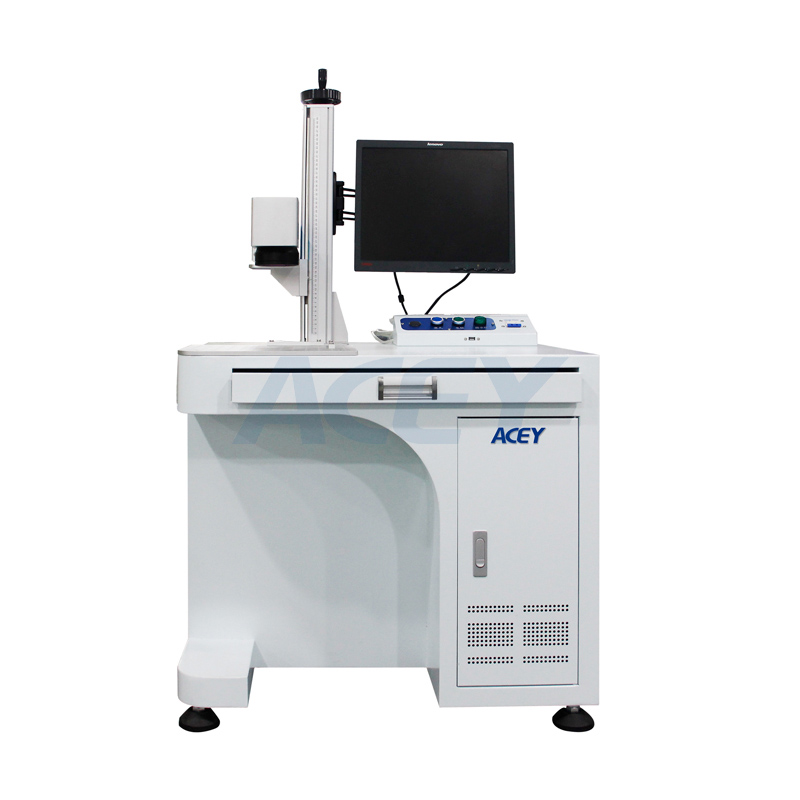

| Laser Cleaning Machine | 30W, 50W, 100W Optional |

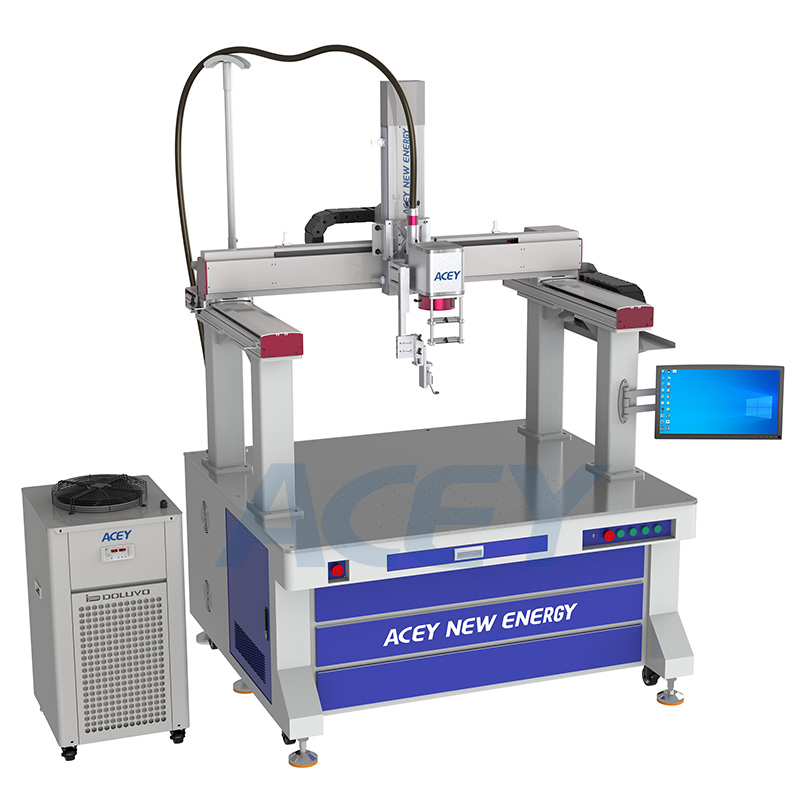

| Laser Welding Machine | 1000W, 1500W, 2000W, 3000W, 4000W, 6000W Optional |

| BMS Tester | 1-52 Series, 120A-800A Optional |

| Battery Pack Comprehensive Tester | Voltage: 60V-200V, Peak Current: 120-600A Optional |

| Battery Aging Machine | Voltage: 20-1650V Discharge Current: 10A-1200A |

Product Display

Tags :