What Are You Looking For?

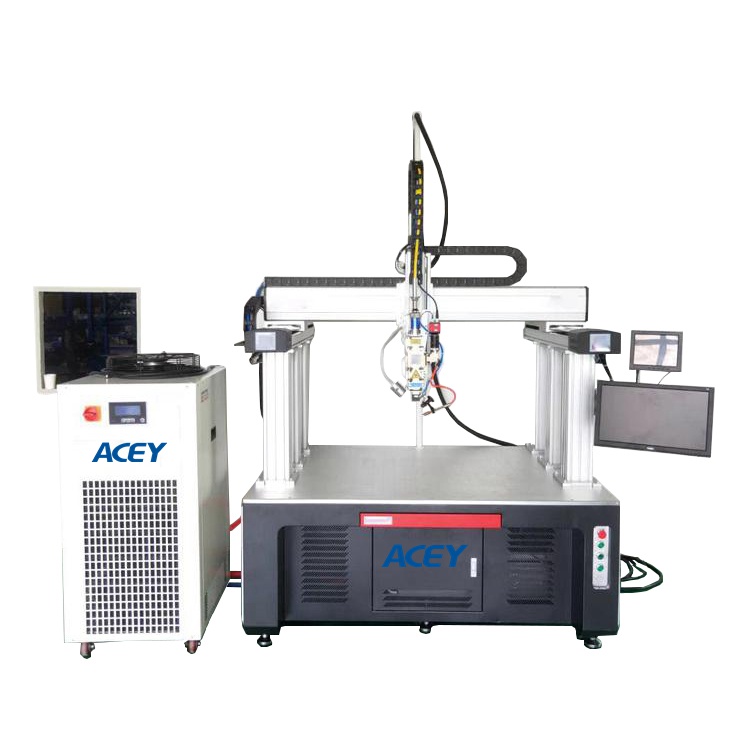

ACEY-3753A is mainly used for welding 18650 Tesla batteries, 26800 lithium batteries, square batteries and other products.

Brand :

ACEYItem No. :

ACEY-3753ACustomization :

OEM&ODM AvailableOrder(MOQ) :

1 SetCompliance :

CE CertifiedPayment :

T/T, L/C, PayPal, West Union, Alibaba Trade Assurance, EtcWarranty :

One Year Warranty With Lifetime SupportProduct Origin :

ChinaPackage :

Internal: Anti-Collision Protectio, External: Plywood CaseShipment :

By Air, Sea, Express, etc.

Product Description

ACEY-3753A is the first automatic ultrasonic thick aluminum wire welding machine in the country to use the rotary welding head method. It adopts a digital automatic frequency tracking ultrasonic system, a digitally controlled pressure adjustment function, a first-class image recognition device, and a fully closed loop motion control circuit. Realize the full automation of China's thick aluminum wire bonding machine.

Features

Manual (front-end station) loading, automatic identification and positioning, automatic bonding, manual (flowing into the back-end station) unloading.

This assembly machine is dedicated to the bonding production of battery products specified by the customer. Non-universal equipment.

If other products are needed, they need to be modified and used according to actual conditions.

This machine is mainly composed of frame assembly, XYZC feeding assembly, automatic feeding mechanism, wire feeding mechanism, jig positioning and pressing assembly, welding head mechanism and console.

XYZ module uses precision ball screw drive, the distance repeat positioning accuracy is less than ±0.02mm, and the angle positioning accuracy is ±1°.

The control system adopts industrial computer + motion control card to control the operation of the private server motor. The equipment is easy to operate and maintain, the control interface is friendly, and the parameter setting is digital; it is more flexible.

Using quick clamp clamping, single button start, easy and safe for personnel to discharge materials.

Left-in and right-out can be used for online multi-section track transmission, which can be directly connected to the production line.

Machine Technical Parameters

| Power supply | 220VAC±10%, 50Hz, maximum consumption rate 1200W |

| Ultrasonic power | 0~30W |

| Weldable aluminum wire diameter | 125~ 500um (5~20mil) |

| XY axis | 400 × 400 (customized) |

| Z axis | 100mm |

| C axis | 180° |

| Ultrasound time | 10~500ms |

| Welding pressure | 50~1200g |

| Welding angle | ±90 degrees |

| Vision system | PR microscope magnification is 0.5 times |

| PR lighting lamp | white light, adjustable brightness |

| Overall dimensions | 1500*2200*1650mm(L*W*H) |

| Weight | 800KG |

Product Display

*Related Products

Tags :