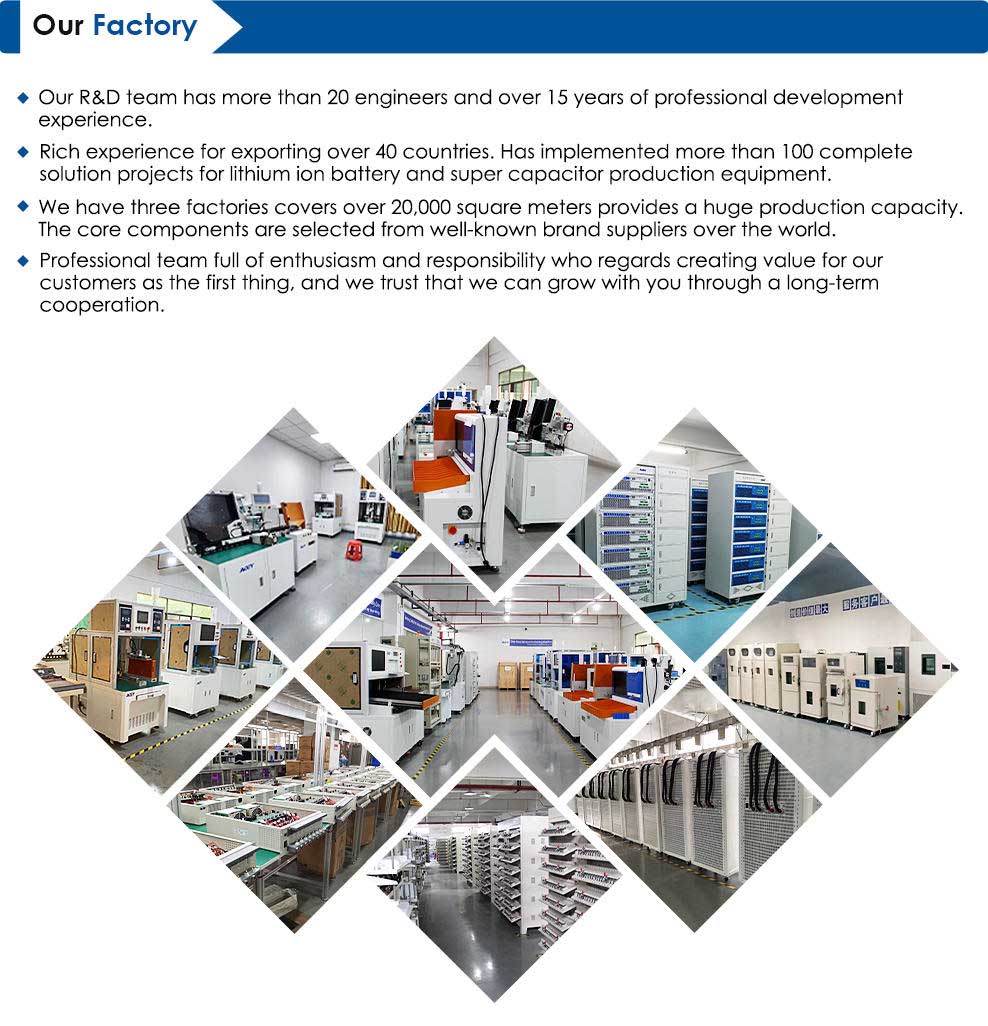

What Are You Looking For?

ACEY-EF-1 is suitable for high-end micro-liquid precision metering, such as various liquid media in the industries of medicine, electrolyte, acid, solvent, dairy products, glue, reagent, etc.

Brand :

ACEYItem No. :

ACEY-EF-1Customization :

OEM&ODM AvailableOrder(MOQ) :

1 SetCompliance :

CE CertifiedPayment :

T/T, L/C, PayPal, West Union, Alibaba Trade Assurance, EtcWarranty :

One Year Warranty With Lifetime SupportProduct Origin :

ChinaPackage :

Internal: Anti-Collision Protectio, External: Plywood CaseShipment :

By Air, Sea, Express, etc.

Product Description

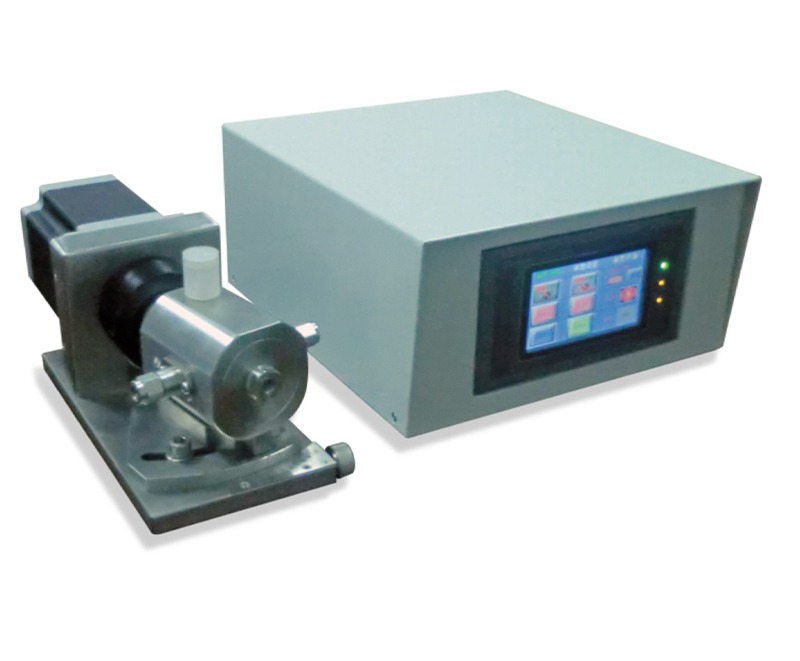

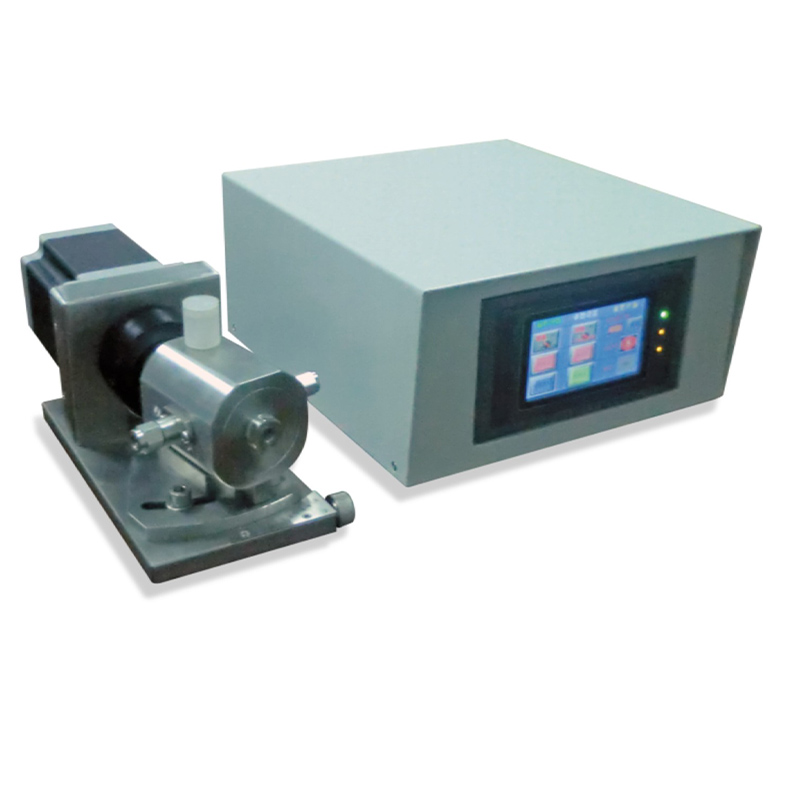

The high-precision electric metering pump uses the connection of the coupling and the stepping motor to drive the plunger rod to reciprocately rotate in the ceramic cavity, forming a reciprocating valve direction switch between the liquid inlet and the liquid outlet. So as to achieve the goal of accurately controlling the inflow and outflow of the liquid medium.

Features

Parameter

| Product type: | Single head 1 output 1 reciprocating rotary positive displacement industrial ceramic plunger metering pump | ||||||

| Pump core material: | ZrO₂, Al₂O₃ | ||||||

| Pump core performance: | Corrosion resistance, high temperature resistance, wear resistance, high hardness, low friction coefficient, long life | ||||||

| Pump core matching accuracy: | 2μm | ||||||

| Drive method: | Imported Servo Motor/Stepper Motor | ||||||

| Range of rotation: | 1-1200rpm forward and reverse reversible | ||||||

| Quick control method: | pulse | ||||||

| Control display method: | Research and control 4.3 inch touch screen man-machine interface dialogue operation | ||||||

| Programming software: | Imported Panasonic programmable controller | ||||||

| Storage performance: | The memory can store parameters and up to 100 recipes | ||||||

| Single stroke capacity range: | 0μL-10000μL Max10000 /1 stroke range | ||||||

| Capacity calculation method: | Q total (total amount of liquid meter) = Q stroke(stroke amount) × N stroke (stroke number) | ||||||

| Measurement accuracy: | Within five thousandths | ||||||

| Applicable medium temperature: | The temperature of the medium liquid is less than or equal to 250℃ (due to different materials, please specify when placing the order) | ||||||

| Catheter: | PE/Teflon/Inlet inner diameter Φ6, outer diameter Φ8, outlet inner diameter Φ6, outer diameter Φ8 | ||||||

| Discharge needle: | Φ2.5/Φ4.0/Φ6.0 (Needle and needle length optional) | ||||||

| Measuring pump size: |

L×W×H 201×125×147mm | ||||||

| Controller size: | L×W×H 295×215×157mm | ||||||

| Weight: | ≈7.3kg including controller and metering pump | ||||||

| Applicable power supply: | AC 220V±10%, 50Hz/60Hz (standard) AC 110V±10%, 50Hz/60Hz (optional) | ||||||

| Working environment: | Temperature 0~40℃, relative humidity <80% | ||||||

| Protection level: | IP31 | ||||||

| Safety performance: | Password protection and factory recovery function to ensure that the set parameters are not modified at will | ||||||

Product Display

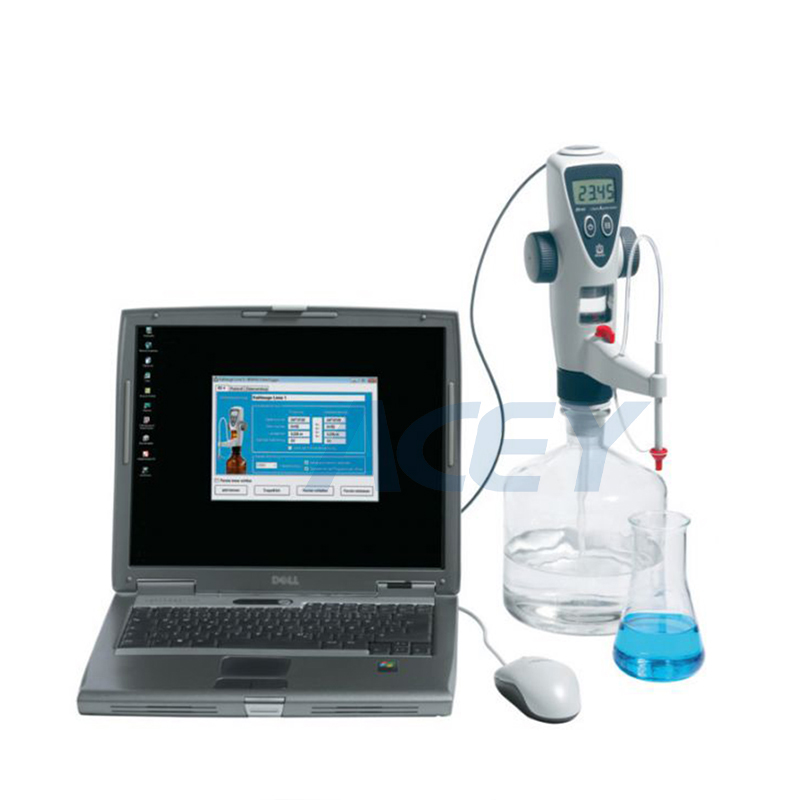

*Related Products

Tags :